Bulk containers are specially designed for shipping powder or granular cargoes, such as soybeans, rice, various feeds, etc. They have loading ports at the top and unloading ports at the bottom to improve loading and unloading efficiency, reduce dust pollution, and enhance cargo quality.However, improper loading of cargo might cause tipping hazards. This article introduces the common safety issues and solutions for bulk cargoes.

Due to the dense characteristics of grains, containers may become overweight or overloaded; the loading capacity should be limited by weight rather than volume. Once fully loaded, the container should not exceed its designated maximum gross weight (to ensure it is not overloaded), nor should it exceed any specified weight limits throughout the intermodal transport process (when the container is overweight).

Shifted center of gravity. The most common cause is improper loading operations, but it can also result from rough handling during intermodal transport. This can potentially lead to vehicle overturning or derailing.

If grain cargo on the ship ruptures and leaks, it can cause serious problems to the ship's bilge water system. The associated cleanup is both complex and expensive.

Pest contamination. Given the nature of the cargo, there is an inherent risk of unwanted pests entering the transport chain and ultimately reaching the destination country. Some pests, like the grain beetle, can hide in containers for years. Similarly, leaks during dock handling or land transport can attract birds and pests, risking human health or personal injury.

Dirty containers can contaminate grain cargo, typically due to the residue and toxic substances from the previously transported goods.

Uneven overall weight distribution of the cargo, with significant rises and depressions on the surface of the grains;

When using multiple isolation spaces for transport, there is a large difference in grain weight between different spaces.

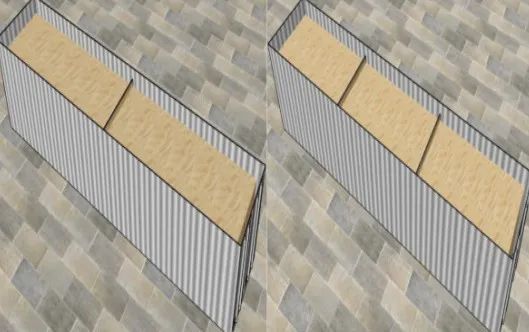

Set up isolation spaces inside the container

For highly mobile bulk grains, isolation spaces should be set inside thelarge bulk container (with partitions installed at the 1/2, 1/3, and 2/3 lengths of the container) to create several independent spaces. The partition's left and right sides should be embedded and fixed into the container's side wall grooves.

Pile evenly and flatly

Large Bulk Containers - The grain piles in each independent space should be fundamentally equal. The surface of bulk grains should be effectively leveled to ensure no significant rises or depressions.

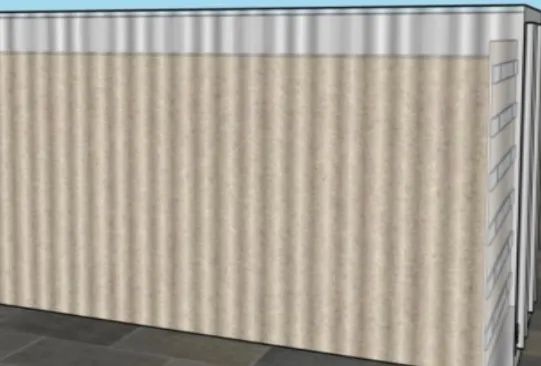

Set up a barrier at the door end

Large Bulk Containers - The door end must be equipped with a barrier of sufficient strength to prevent grain spillage. The barrier's left and right sides should be embedded and fixed into the container's side wall grooves, and the barrier height should be higher than the bulk grain stack height.

Photographs and illustrations of compliant loading plans